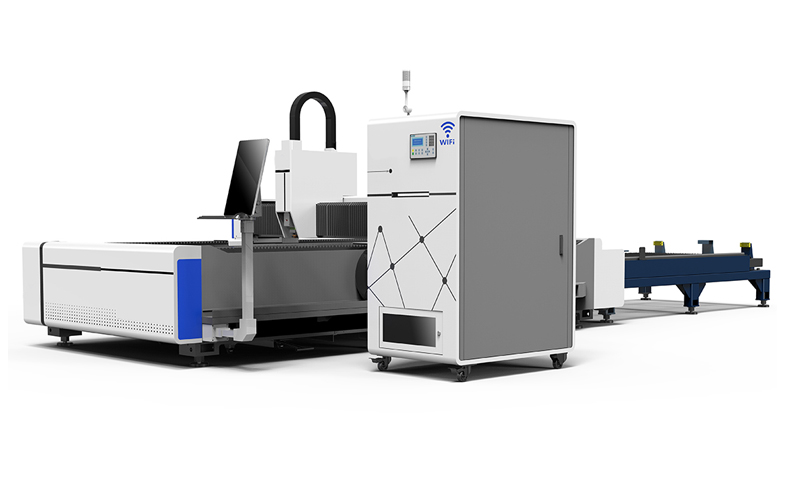

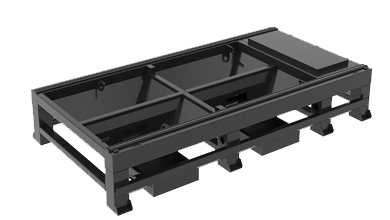

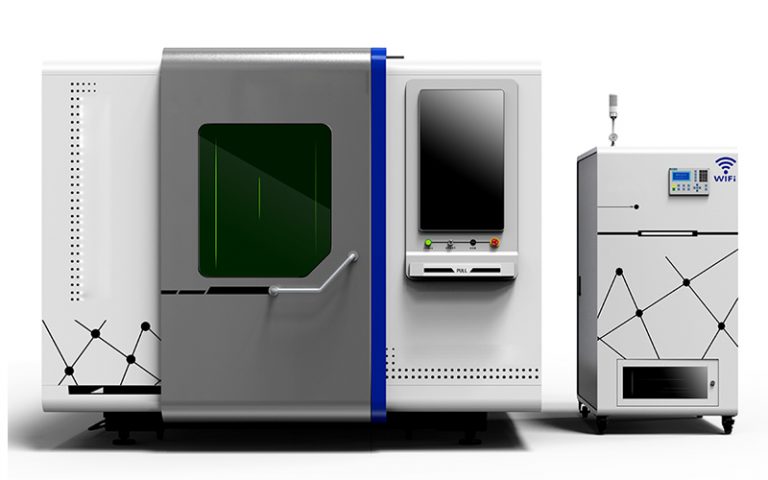

Fully Enclosed Protective Cover Design

It can be equipped with a fully enclosed laser protective cover (with a special laser protective glass observation window), and a fume recovery and purification system to reduce light pollution and smoke pollution caused by laser cutting during equipment operation. And we are equipped with high-definition monitoring equipment to achieve 360° monitoring in the cutting state to prevent misoperation.