After long-term technology accumulation and industrial application practice, the laser processing industry has formed a complete industrial chain system. At present, various sheet metal products in life may come from the masterpieces of laser cutting machines. The following is a detailed introduction to which aspects of the currently popular industries are applied:

1. Kitchenware Industry—-Application of Laser Cutting Machine

Kitchenware is one of the indispensable metal products in our daily life. The traditional processing methods in the kitchen utensil production industry face the problems of low work efficiency, large consumption of molds, and high cost of use. The laser cutting machine has fast cutting speed and high precision, which improves the processing efficiency, and can realize customized and personalized product development, solve the troubles of kitchenware manufacturers, and has won the recognition of kitchenware manufacturers.

2. Automobile manufacturing industry—-Application of laser cutting machine

There are also many precision parts and materials in automobiles, such as automobile brake pads. In order to improve the safety of automobiles, it is necessary to ensure the cutting accuracy. The traditional manual operation accuracy is difficult to achieve, followed by low efficiency. Laser cutting can be used for faster batch processing. High precision, high efficiency, no burrs, and one-shot molding are the reasons why laser cutting machines are widely used in the automotive industry.

3. Fitness equipment industry — Laser cutting machine application

The diversity of fitness equipment also puts forward high requirements for processing. Various specifications and shapes make traditional processing complicated and inefficient. Laser cutting has high processing flexibility, and can carry out customized flexible processing for different pipes and plates, and the finished product after processing is smooth and burr-free, without secondary processing, and the quality and efficiency are greatly improved compared to traditional processes.

4. Advertising metal word industry—laser cutting machine application

Advertising traditional processing equipment generally uses materials such as processing advertising fonts. Due to the unsatisfactory processing accuracy and cutting surface, the probability of rework is quite large. The high-precision laser cutting technology does not require secondary rework, which greatly improves work efficiency and saves enterprise costs.

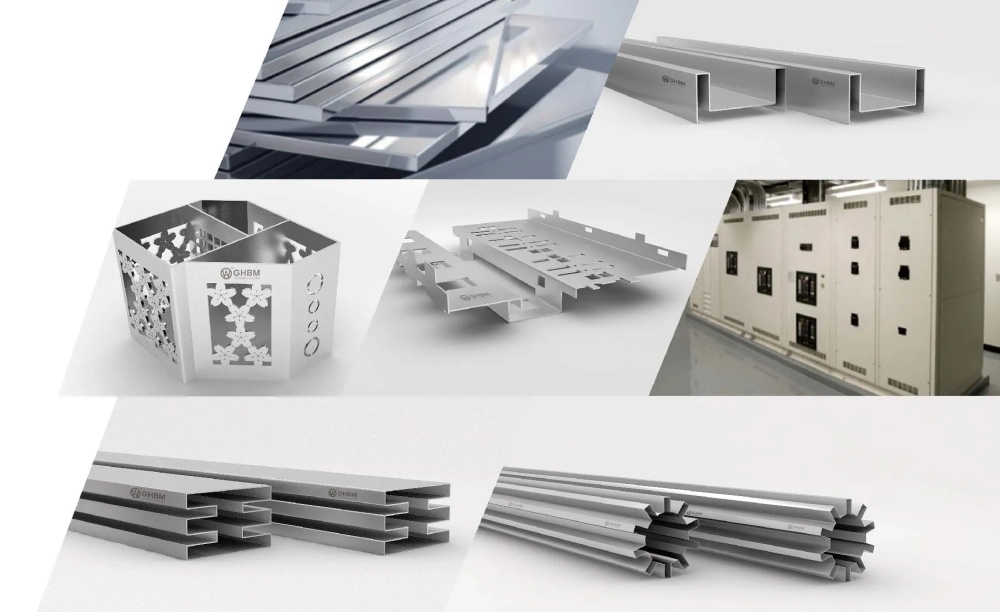

5. Sheet metal processing industry—laser cutting machine application

With the rapid development of sheet metal processing technology, traditional sheet metal cutting equipment can no longer meet the requirements of current technology and cutting shape. Laser cutting has gradually replaced traditional equipment with the advantages of high flexibility and fast cutting speed. Fiber laser cutting machine Widespread application in sheet metal processing is an inevitable trend.

6. Chassis and cabinet industry—laser cutting machine application

The power distribution cabinets, file cabinets, etc. we see in our lives are all products produced by standardization of thin plates, and have high requirements for efficiency. Using a laser cutting machine with four or six stations is relatively suitable and has high efficiency at the same time. , it can also achieve double-layer cutting for specific plates.

7. Agricultural machinery industry — laser cutting machine application

With the continuous development of agriculture, the types of agricultural machinery products tend to be diversified and specialized, and at the same time, new requirements are put forward for the manufacture of agricultural machinery products. The advanced laser processing technology, drawing system and numerical control technology of the laser cutting machine not only reduce the production cost of agricultural machinery and equipment, but also improve the economic benefits.

8. Shipbuilding industry–laser cutting machine application

In the field of shipbuilding, the marine steel plate cut by laser has good kerf quality, good verticality of the incision surface, no slag, thin oxide layer, smooth surface, no need for secondary processing, direct welding, and small thermal deformation, curve cutting High precision, reduce working hours, and achieve barrier-free cutting of high-strength ship plates.

9. Automotive industry–laser cutting machine application

In the automotive industry, some parts, such as car doors, car exhaust pipes, etc., will leave some extra corners or burrs after being processed. If they are processed manually or traditionally, it is difficult to ensure accuracy and efficiency. If processed with a laser cutting machine, corners and burrs can be easily solved in batches.

As one of the most intelligent industries at present, automobile manufacturing has integrated a variety of production processes, and laser, as one of the most important technologies, has achieved intelligent production of up to 70% of accessories.

10. Aerospace

Laser manufacturing technology is an important part of aerospace manufacturing technology. Laser cutting processing technology has been widely used in aircraft, aerospace rockets and other accessories, components and other components.

11. Construction machinery industry

Generally speaking, the plates used in the construction machinery industry are mostly medium and thick plates. Bevel laser cutting can solve the problem of blanking and beveling at one time. It has the advantages of high precision, fast speed, high material utilization rate, and reduced labor costs.

There are laser cutting applications in industries such as iron towers, curtain walls, elevators, steel structures, medical equipment, and hoisting machinery.