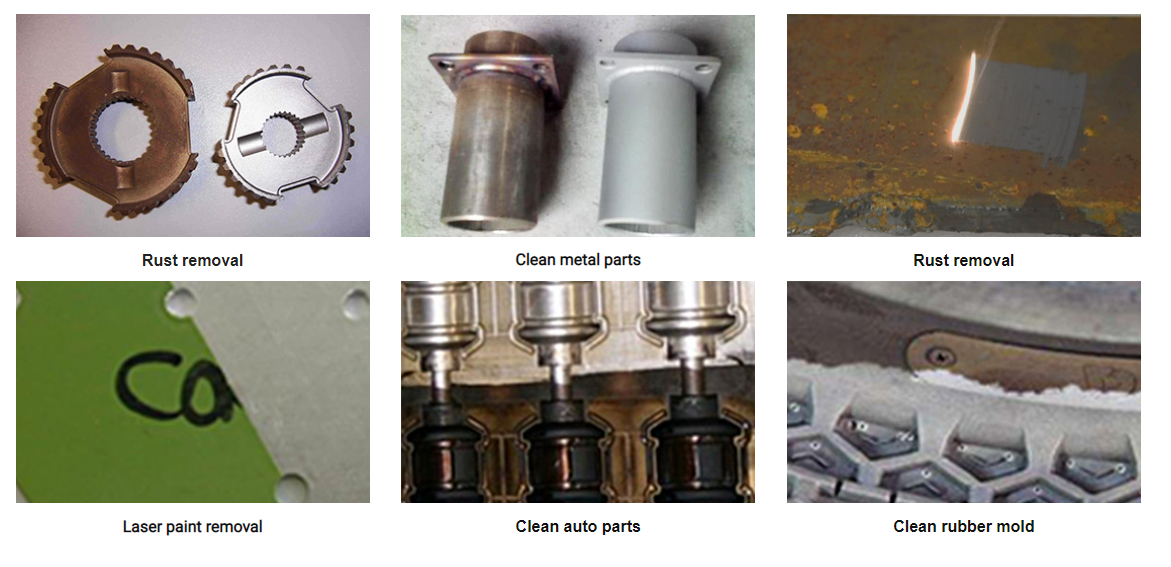

Laser cleaning technology is a new cleaning technology that has developed rapidly in the past ten years. It is gradually replacing the traditional surface treatment cleaning process in many fields due to its many advantages. It can adapt to the cleaning of various surface contaminants, has minimal environmental pollution, and can achieve no damage to the substrate. At present, this method has become a supplement and extension of traditional cleaning methods, and has shown broad application prospects due to its many inherent advantages. The advantages of laser descaling machine have the following 5 points:

1. Wide application range:

The laser cleaning machine can remove various types of contaminants on the surface of various materials to achieve a cleanliness that cannot be achieved by conventional cleaning. Furthermore, contaminants on the surface of the material can be selectively cleaned without damaging the surface of the material.

2. Easy to operate:

The laser cleaning machine can be transmitted through optical fiber and cooperate with robots to realize long-distance operation. It can clean the complex parts that are difficult to reach by traditional methods. This feature also makes the safety of operators more secure in some dangerous places.

3. High cleaning efficiency:

The cleaning efficiency of the laser cleaning machine is very high, and the laser rust removal has no grinding, non-contact, and no thermal effect. It will not produce mechanical force on the object to be cleaned, and will not cause damage to the surface of the object to be cleaned, and it does not need to be cleaned. Using any chemicals and cleaning fluids will not pollute the environment.

4. Green environmental protection:

There is no need to use any chemicals and cleaning solutions, and the cleaned waste is basically solid powder, small in size, easy to store, recyclable, no photochemical reaction, and no pollution.

5. Low cost:

The initial investment of laser cleaning system is high, but it can be used stably for a long time. It has low operating cost, high speed, high efficiency, time saving, and can quickly get a return on investment. In the long run, the cost is lower than traditional cleaning methods.

After talking about the advantages of laser cleaning machine, let’s talk about the disadvantages of laser cleaning machine. As the country’s requirements for carbon emissions become more and more stringent, and the requirements for the transformation and upgrading of the manufacturing industry are becoming more and more clear, green, environmentally friendly, high-efficiency and energy-saving laser cleaning has gradually formed a dimensionality reduction attack on industries such as sandblasting and wet chemical cleaning. I believe that in the near future, laser cleaning will definitely replace the traditional cleaning industry and become a subversive in the field of industrial cleaning!